Confined spaces are often out of sight and out of mind—until something goes terribly wrong. In many industries across Middle Tennessee, from construction to craft brewing, these environments pose some of the most severe workplace hazards imaginable.

Whether you’re overseeing a brewery in East Nashville, managing a telecom utility project in Murfreesboro, or operating a wastewater treatment plant in Franklin, one truth remains: confined space safety cannot be an afterthought. It must be proactively integrated into your daily operations with proper hazard assessments, continuous training, and full compliance with OSHA and TOSHA regulations.

That’s where Fortier Loss Control Consultants comes in.

As a trusted safety partner for businesses throughout the Nashville metropolitan area and beyond, Fortier Loss Control helps employers identify, mitigate, and manage confined space risks—before they result in serious injury, regulatory violations, or costly downtime.

Let’s explore what every Nashville-area employer should know about confined space hazards—and how Fortier can help your organization stay ahead of the curve.

The Hidden Dangers: Understanding Confined Spaces in Nashville’s Industries

As Nashville continues to expand, so do the industries that rely on confined spaces as part of routine operations. Whether it’s a high-profile construction project downtown or production in a legacy manufacturing facility, confined spaces are more prevalent—and more dangerous—than ever before.

What Is a Confined Space?

According to OSHA, a confined space is one that:

-

Is large enough for a worker to enter and perform assigned tasks;

-

Has limited or restricted means of entry or exit;

-

Is not designed for continuous occupancy.

These characteristics create dangerous working conditions that can lead to oxygen deprivation, toxic gas exposure, engulfment, and limited rescue options.

Real-World Examples Across Nashville’s Industrial Sectors:

-

Fermentation tanks in East Nashville’s booming craft beer and distillery scene. These spaces often have elevated levels of carbon dioxide (CO₂), posing a deadly atmospheric hazard.

-

Utility vaults and underground access points in rapidly expanding telecom and fiber optic installations. These tight spaces often have limited ventilation and pose electrocution or trench collapse risks.

-

Culverts, storm drains, and sewer lines in public infrastructure and wastewater management. The risk of engulfment, toxic gases like hydrogen sulfide (H₂S), and biological hazards is very real.

-

Storage silos and hoppers in Middle Tennessee’s food production and manufacturing facilities. Workers inside may face engulfment in grain, flour, or powder, especially during cleaning or maintenance tasks.

-

Basements, crawlspaces, and attics on construction sites. These may seem familiar but can present serious hazards if not properly assessed—especially during demolition or mechanical installation work.

In all of these environments, a small misstep, a shift in air quality, or a lapse in protocol can quickly lead to a life-threatening emergency.

Why Confined Space Safety is Non-Negotiable

Many confined space incidents result from a lack of awareness or preparation. Unfortunately, they are rarely isolated—they often affect multiple workers, especially when coworkers rush in to help without proper equipment or training.

According to national safety data:

-

Over 60% of confined space fatalities are would-be rescuers.

-

Most confined space deaths occur in poorly ventilated, permit-required spaces.

-

Many employers are unaware of the regulatory classification of their workspaces, leading to insufficient protection and non-compliance with safety laws.

Given these sobering facts, confined space safety is more than just another box to check—it’s an essential part of your business’s responsibility to protect workers, maintain legal compliance, and ensure operational continuity.

Is It a Confined Space? Recognizing and Classifying Work Areas

Proper classification is essential, and it’s not always as straightforward as it seems. Many employers mistakenly believe that “tight” or “awkward” spaces are the same as confined spaces. In reality, OSHA’s definition includes specific criteria—and misclassifying a space can lead to serious consequences.

Let’s take a real-world example:

Imagine a contractor working in a stormwater drain in South Nashville. The space is large enough to enter, has only one exit, and isn’t meant for ongoing occupancy. That meets the criteria for a confined space.

Now add the presence of hydrogen sulfide gas from sewage runoff, and it becomes a permit-required confined space.

Fortier Loss Control helps companies in Nashville perform formal confined space audits—including atmospheric testing, layout evaluation, and work activity assessments—to determine the correct classification and safety controls.

Nashville’s Silent Killers: Top Confined Space Hazards (Atmospheric, Engulfment & More)

In Tennessee, confined space accidents are unfortunately more common than most employers realize. One study from the CDC found that 60% of confined space fatalities are would-be rescuers—often coworkers acting on instinct without proper training or PPE.

Additional Hazards Found in Nashville Industries:

-

Fermentation Off-Gassing: Breweries and distilleries produce CO₂ in large volumes. Without proper ventilation, it can displace oxygen and cause unconsciousness within minutes.

-

Welding in Confined Spaces: Metal fabricators or industrial contractors in Davidson County may work in small tanks or silos, introducing both toxic fumes and fire risks.

-

Ammonia Leaks: Cold storage facilities in the food sector use ammonia-based refrigeration systems, which can pose inhalation risks in confined areas.

Even with ventilation, a space’s atmospheric conditions can change unexpectedly, especially when multiple trades are working simultaneously. Fortier’s risk assessment process ensures continuous hazard monitoring, not just pre-entry testing.

Navigating the Maze: OSHA and TOSHA Confined Space Regulations Explained

Both OSHA (federal) and TOSHA (state-level) apply to Tennessee businesses. While they share core principles, enforcement in Tennessee can be more localized and proactive, especially in industries like construction and utilities.

Key regulatory highlights include:

-

Pre-Entry Hazard Evaluation

-

Permit Program Development

-

Employee Training & Competency Verification

-

Emergency Response Plans

-

Atmospheric Testing Requirements

-

Procedures for Isolating Hazards (LOTO)

Fortier Loss Control doesn’t just interpret the regulations—we translate them into actionable policies, tailored to each facility or jobsite in Nashville. Whether you’re dealing with a legacy silo from a 1940s bottling plant or a brand-new underground fiber line install, we ensure your safety plan meets or exceeds the law.

Construction vs. General Industry: Key Differences Nashville Businesses Must Know

For many Nashville-area companies, workers shift between general industry and construction environments. A team might be maintaining a food processing tank one day, then installing piping the next. These transitions trigger different regulatory requirements.

Example Scenario:

A general contractor working on a brewery expansion in East Nashville is subcontracted to install new grain silos. During installation, Subpart AA (Construction) applies. Once operational, the brewery becomes a general industry site, governed by 1910.146.

Employers must adjust their procedures accordingly, or risk non-compliance. Fortier Loss Control provides gap analyses and crossover training to help crews transition safely between work types, roles, and project stages.

The High Cost of Non-Compliance: Risks Beyond Fines in Tennessee

Compliance isn’t just about avoiding citations. The real costs come in many forms:

-

Civil lawsuits: Injured employees or their families may sue for negligence.

-

Increased insurance premiums: One incident can cause premiums to spike for years.

-

Lost productivity: Investigations, site shutdowns, and equipment quarantines disrupt schedules and hurt the bottom line.

-

Brand damage: For businesses like distilleries or manufacturers with public tours, safety incidents can erode consumer trust.

TOSHA inspections are unannounced, and whistleblowers are protected. That means if even one worker feels unsafe or improperly trained, a surprise inspection could follow.

Fortier Loss Control’s Approach: Tailored Safety for Nashville’s Unique Needs

What makes Fortier different? It’s our deep understanding of Nashville’s industrial ecosystem and our commitment to building relationships, not just delivering paperwork.

We don’t offer cookie-cutter solutions. Instead, we provide:

-

Custom safety programs based on your industry and workspace

-

Worksite walkthroughs and hazard mapping

-

Employee interviews to uncover gaps in understanding

-

Integration with your existing SOPs and management systems

-

Continuous improvement support with audits, updates, and on-call advice

With Fortier Loss Control, you’re not just checking boxes—you’re building a proactive culture of safety that pays dividends in morale, compliance, and operational efficiency.

Beyond the Basics: Fortier’s Comprehensive Confined Space Training Programs

Your team is your front line of defense. We empower them with practical, hands-on training that sticks.

Training includes:

-

Entry Supervisor Certification

-

Gas Monitor Use & Calibration

-

Lockout/Tagout Procedures in Confined Spaces

-

Ventilation and Air Exchange Techniques

-

Pre-entry Checklists and Permitting

-

Live Rescue Simulations

Courses are available in-person at your jobsite, at our training center, or via remote learning modules—perfect for multi-site organizations or rotating shift teams.

And unlike generic online courses, our training includes Nashville-specific scenarios, hazards, and case studies—making it directly relevant to your people.

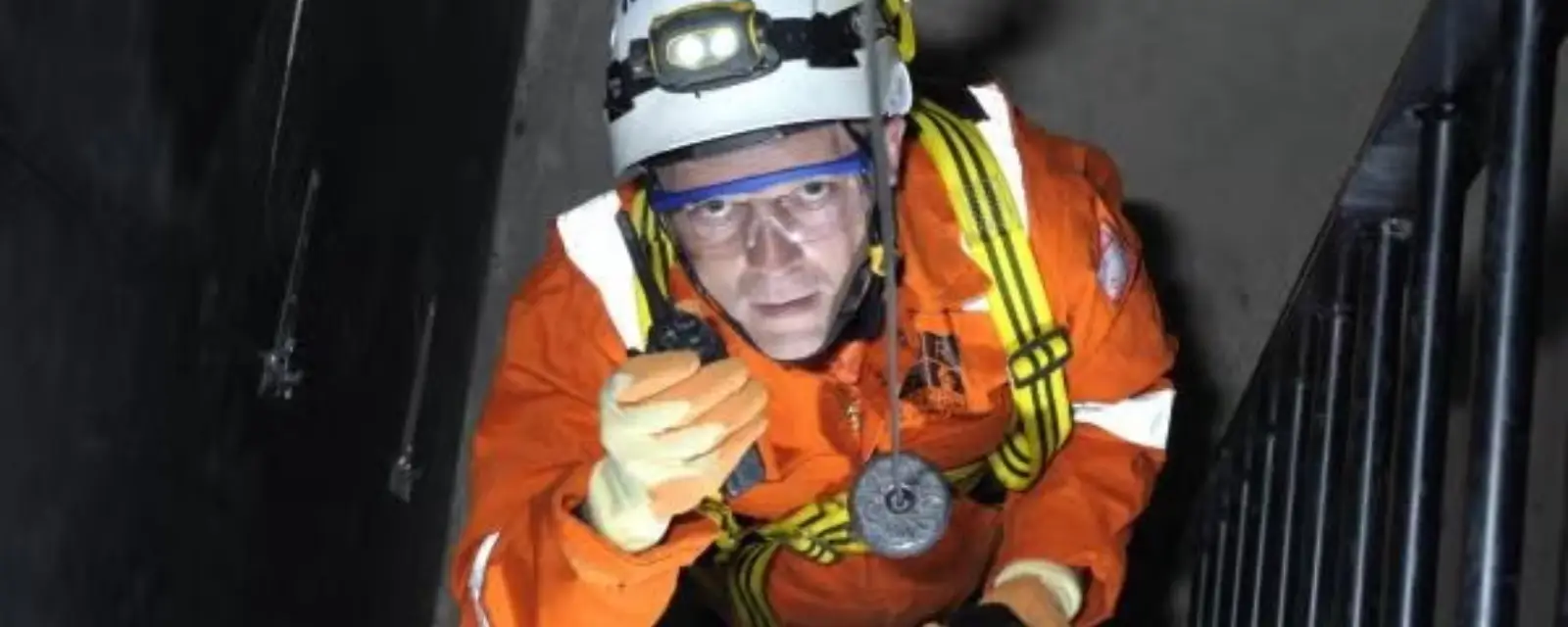

Preparing for the Worst: The Importance of Confined Space Rescue Planning

A rescue plan isn’t just a binder on a shelf—it’s a living, breathing system. Fortier Loss Control helps you bring it to life with:

-

Role assignments (entrant, attendant, supervisor, rescuer)

-

Rescue equipment readiness checks

-

Coordination with Nashville-area emergency responders

-

Clock-based response planning (e.g., <4 minutes for IDLH spaces)

-

Annual rescue drills and documentation

We also offer third-party rescue team audits to evaluate your readiness and compliance with 29 CFR 1910.146(k) or Subpart AA’s equivalent.

Frequently Asked Questions

Conclusion

Confined spaces present serious and often underestimated risks, especially in industries thriving across the Nashville area—from construction and manufacturing to utilities and beverage production. But with the right approach, these risks can be effectively managed, lives can be saved, and operations can run smoothly and compliantly.

Fortier Loss Control Consultants brings unmatched expertise, local industry knowledge, and a proactive, hands-on approach to confined space safety. Whether you need help identifying hazards, training your team, developing a compliant safety program, or preparing for emergency rescue, Fortier is your trusted partner.

Don’t wait for an incident to force your hand. Take control of your confined space safety today—and let Fortier help you build a safer, stronger future for your workforce and your business.